The following is a list of important questions related to your current investment in molds and tooling:

The following is a list of important questions related to your current investment in molds and tooling:

- How much are you spending on molds/tooling each year?

- Are they lasting for as many production cycles as they were engineered for?

- Does your company measure the number of production cycles your molds produce versus the projected number of cycles the tooling manufacturer made when you were evaluating the payback analysis?

- What is the true cost per production/part cycle versus the real “life cycle” of the tooling?

- How can we save you $1 million dollars in a year?

Companies that manufacture molded products that include “sticky” ingredients such as candy (basically any product with sugar), adhesive-backed printed labels, or the latest generations of high-performance aerospace composite resins (like those used to mold the fuselage spars and components for the Boeing 787…) ALL of these processes inevitably lead to sticky production issues, quality control problems, and lost profits when production is halted due to molds sticking to the molded parts as the original mold release/non-stick coatings wears off.

The tooling manufacturer isn’t necessarily at fault if the manufacturer doesn’t properly maintain the non-stick coating on the tooling. After all, metal is stronger than any non-stick coating… so, when the coating wears off, wear and tear accelerates.

Improving the Efficiency of Tooling

ECS works with a broad range of clients who recognize the value of keeping their tooling working efficiently by having their molds recoated with non-stick coatings ranging from PTFE-based fluoropolymers to Sol-Gel technologies. Some of these clients cycle their tools out frequently, sometimes several times a month to be recoated. The problem this can create however, is when the worn coating is blasted off to prep for a new application, the blasting process is slowly eroding the metal below it also.

Over time, the erosion is enough to render the tooling dimensionally obsolete and the tooling scrapped. To overcome this, we utilize walnut blast media to remove the original coating instead of blast media. Because the walnut media is harder than the coating, but softer than the metal, there is no erosion.

While we charge slightly more for this process, the tooling’s operational life is extended significantly. In a recent case study, whereas our client had been replacing the tooling each year, they have extended it to two years… and counting. We saved them the equivalent of $1 million because they don’t have to buy replacement molds as often.

How much money can we save your company? Let’s talk.

What does it mean to be Food-Grade?

What does it mean to be Food-Grade? By Angela Conrow, Controller at Extreme Coating Solutions

By Angela Conrow, Controller at Extreme Coating Solutions

One of Extreme Coating Solutions (ECS) clients inquired whether we could provide a semi-permanent coating that would allow them to discharge the remaining LDPE resin they used for laminating large animal feed bags.

One of Extreme Coating Solutions (ECS) clients inquired whether we could provide a semi-permanent coating that would allow them to discharge the remaining LDPE resin they used for laminating large animal feed bags.

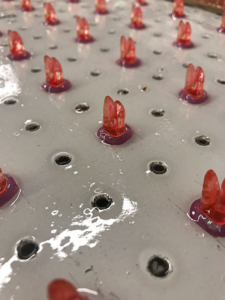

One unique project that we provide the final finishes for at our facility involves acrylic teeth replicas used as teaching tools for dental students. In the beginning, there were a number of different coating options we tested to achieve our client’s specific criteria. Collaborative work with the client included the development of customized painting jigs, which not only minimized variables that could result in quality issues, but also minimized the handling required to process the parts.

One unique project that we provide the final finishes for at our facility involves acrylic teeth replicas used as teaching tools for dental students. In the beginning, there were a number of different coating options we tested to achieve our client’s specific criteria. Collaborative work with the client included the development of customized painting jigs, which not only minimized variables that could result in quality issues, but also minimized the handling required to process the parts.